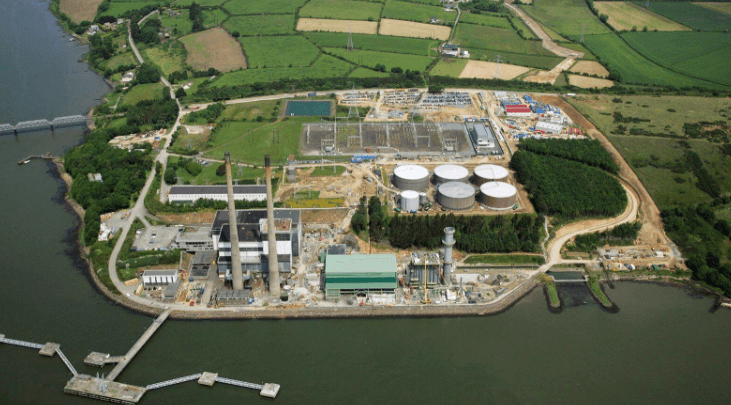

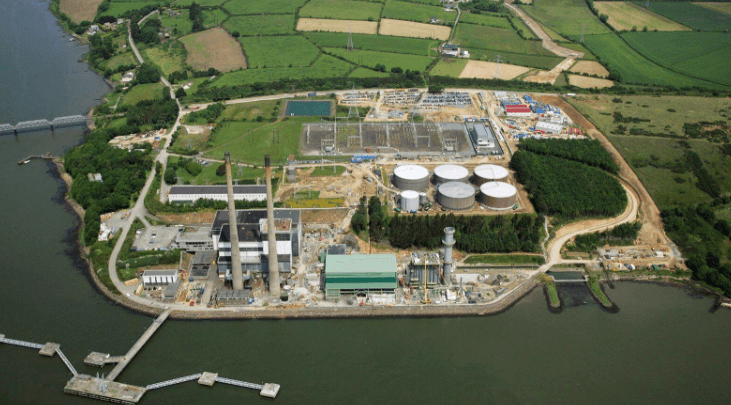

Project Overview

AQL was engaged to complete active water stopping by resin crack injection methods to two tanks in a power station. 1300 linear metres of cracks were injected, filled and overcoated. Pipe penetrations were injected, along with the installation of as screed and a heat-resistant coating to an inlet chamber. After the completion of works, all cracks were sealed and protected for many years to come.

client objectives

Scope of works

AQL carried out active water stopping methods and a restoration to inlet chamber, including: Crack Injection- 1300 linear metres of cracks were injected to stop any water ingress/egress. Holes were drilled every 200mm, injecting nipples installed and resin pumped into cracks. Protecting Cracks- After the injection was completed, all cracks were filled and a heat-resistant coating was applied to protect the concrete Pipe Penetrations- Crack injection was also completed around all pipe penetrations to stop any water egress through these voids. Screed- The floor of the inlet chamber was scabbled to create an optimal surface to apply the screed. The floor was then primed and a level 60mm screed was installed. Heat-Resistant Coating- A heat resistant lining was then applied to the inlet chamber to protect the new screed from the hot water entering.